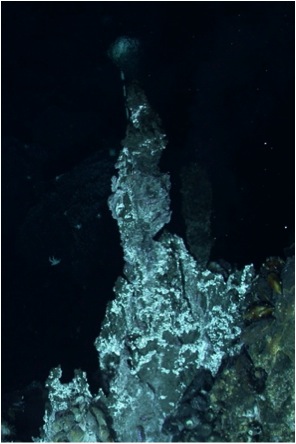

One of the major challenges when sampling the deep waters is that all manipulations must be done with an arm which, even at maximum extension, has the grip force to pick up a 250lbs rock. This ability is very useful when one wants to pick up a 250lbs rock; however, sampling feather-light sulfur beehives becomes somewhat of an ordeal. Hard handling can result in a cloud of beehive dust. When Chief Scientist, Anna-Louise Reysenbach, jokingly challenged the Jason team to create a dainty tool able to successfully sample these tricky formations, she thought it couldn’t be done.

Jason engineer, Dara Scott (pictured above with the FST3000), took on the challenge. Ingenious Irish inventor that he is, Dara came up with a device that not only sampled beehives without touching them, but was also environmentally friendly. The FST 3000 recycled an ordinary tin can into a superb beehive sampler. It cuts the beehive off at its stem and gently cradles the delicate sample until it can be placed in the storage box to be taken to the surface safely. The powerful grip of the Jason arm is reduced, only being used to force the FST to cut the stem.

Jason engineer, Dara Scott (pictured above with the FST3000), took on the challenge. Ingenious Irish inventor that he is, Dara came up with a device that not only sampled beehives without touching them, but was also environmentally friendly. The FST 3000 recycled an ordinary tin can into a superb beehive sampler. It cuts the beehive off at its stem and gently cradles the delicate sample until it can be placed in the storage box to be taken to the surface safely. The powerful grip of the Jason arm is reduced, only being used to force the FST to cut the stem.

The scientific community is agog, fueled by the buzz of successful test trials on the mysterious FST 3000. Above, the Jason control van looks on as the FST 3000 gets put into use.

As the galley wonders where all their soup cans keep disappearing to, marketing plans for the FST 3000 are in full swing:

“Do you want control over your chimney breaks?

Tired of throwing away tin cans?

Then get the FST 3000 with EaZe-Break S22

Now with rubberized ergonomically enhanced performance handles,

to really take control of those pesky vent situations.”